Magnetic Resonance Imaging, or simply MRI, is considered an important diagnostic tool in modern medicine, and Philips Healthcare belongs to the class of leading world manufacturers of MRI systems. In the broad sense, healthcare professionals and technicians have to be aware of numerous components of Philips MRI parts concerning operation efficiency and safety for the patient along with diagnostic quality. This post closely looks at major compositions of Philips MRI parts, classifies the components, and identifies the most critical and common ones.

Types of Philips MRI Parts

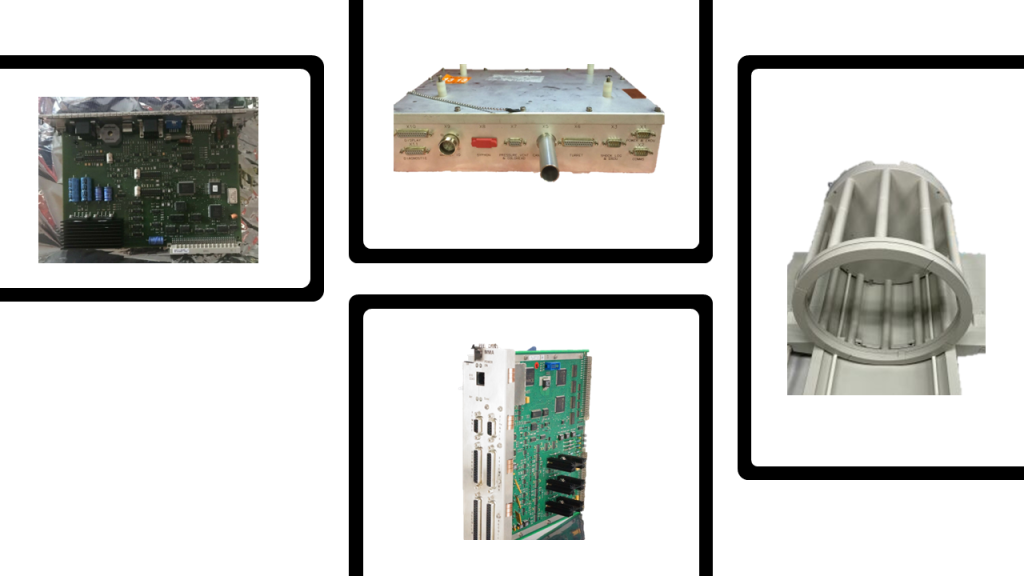

Based on their classification and functionality, Philips MRI parts can be divided into a number of categories:

- Magnet Components: Superconducting magnet includes gradient coils and shim coils. It is the heart of any MRI system because it feeds the strong magnetic field necessary in imaging. Gradient coils spatially encode the MRI signal, while shim coils correct inhomogeneities of magnetic fields.

- RF Components: The category includes RF coils, especially body coils, head coils, and surface coils; RF amplifiers; and transmission cables. RF coils have their major use in transmitting RF pulses to the body of the patient and receiving the resultant signal that is useful in imaging.

- Cryogenic and Cooling Systems: This would include a cooling system making use of cryogens such as liquid helium, which is very important in maintaining the superconductivity state of the MRI magnet. It would include cryocoolers, helium compressors, and the quench pipes-all these take an important part in the maintenance of operating temperature and prevention of system quench.

- Computer and control systems: These include the hardware and software of a computer controlling the operation of the MRI. These include the interface with the user, acquisition of data, reconstruction, and storage of images. The control system further assumes responsibility in signal processing and provides an operating interface to vary imaging parameters.

- Components of Power Supply: These are the essential components that the MRI system needs to operate efficiently. It consists of transformers, units, and UPS applied in the continuity of operation if fluctuation of power occurs.

- Mechanical and Structural Parts: These are the physical parts housing MRI equipment in place, supporting them in position. Thus, it includes the patient table, magnet bore, gradient shield, and outer covers. It ensures stability and proper alignment of the system.

Basic and Highly Consumable Philips MRI parts

Some parts in a Philips MRI system are so important that either due to the wear and tear, they are prone to replacement or because of the usage in the imaging scale, their installation is a must. Such key and most consumed parts are explained below.

RF Coils:

Probably the most critical components of an MRI system are the RF coils, since their performance directly impacts the image quality. They vary based on the type of application:

- Transmit Coils: These coils transmit the RF field that excites the hydrogen nuclei within the body. The most common type of transmit coil is probably the body coil, which is also usually placed inside the MRI bore during whole-body imaging.

- Receive Coils: These would include the coils that receive the RF signals emitted by the excited hydrogen nuclei. Receive coils are usually positioned closer to areas of interest to enhance SNR. Such a receive coil can be a head coil, knee coil, and even a phased-array coil.

- Some of them represent double-function coils, used both in transmission and reception. The examples include the surface coils applied for imaging specific parts of the body with very high SNR and good spatial resolution.

- Maintenance Consideration: The RF coils should be positioned very close to the patient and, therefore, are prone to constant handling and to mechanical damage. They regularly ought to be inspected for wear and tear, cable integrity, and cleaning of the connectors in order to avoid deterioration of the signal.

Gradient Coils:

Spatial encoding is an important modality in constructing MRI images, and the process is handled by the gradient coils. This is very important because they linearly modulate the magnetic field across the scanning area, hence allowing the localization of MR signals.

- X, Y, and Z Gradient Coils: A single gradient coil acts to control the magnetic field gradient along one axis: X, Y or Z. The interaction of these allows other planes such as axial, sagittal and coronal to be scanned.

- Active Shielding Coils: These decrease the extent of a gradient magnetic field outside of the MRI scanner and therefore protect the surrounding area from any magnetic interference.

It should be noted that the gradient coils behave in the manner of potential sources of heating and noise; besides good quality noise attenuation components, regular checks of the cooling systems are in place for acoustic noise removal during operation.

Superconducting Magnet

The superconducting magnet forms the heart of any Philips MRI system and creates a very powerful and stable magnetic field, typically in the range of 1.5 Tesla to 3.0 Tesla, depending upon the requirement specified to be utilized for high-resolution imaging.

- Magnet Windings: These are manufactured from superconducting materials such as niobium-titanium and are submerged in liquid helium to maintain the required superconducting state.

- The cryogenic components include the helium vessel, cold head, and quench pipe. All these three act together to keep the magnet at the needed low temperature, which is about -269°C. The cold head is used to compress the helium gas into liquid for it to maintain the magnet in its superconductivity.

- Maintenance Consideration: This is a critical cooling system and requires periodic helium level checks, cold head inspection and leak or quench conditions that can result in costly system downtime .

Patient Handling System

Other major mechanical components include the patient table, which has to ensure proper positioning for comfort of the patients during scans. The motor drive table shall have to provide smooth and precise motion in and out of the magnet bore.

- Table Drive System: It contains motors, position sensors, and control boards for such precise and reproducible positioning of the patients, which is of utmost importance for consistency in imaging.

- Maintenance Consideration: This, in turn, would make periodic calibration of the drive system together with lubrication of the moving parts necessary to avoid mechanical failure for patient safety.

Helium Compressor and Cooling System

The helium compressor and the associated cooling system are very important and go to maintain the superconducting magnet at a temperature within its operating limits.

- Helium Compressor: Helium gas is pumped onto the cold head, thereby liquefying it and sustaining the low temperature that superconductivity requires.

- Quench Pipe: Quench pipe is used for safe paths for helium gas to go out in case of quenching so that overpressure cannot damage it.

It must also be checked regularly for leakage, wear, and tear, and functionality. Preventive maintenance ensures that there is a constant cooling action and reduces the chances of magnet quench.

The Philips MRI systems comprise quite a few complex parts; each of those Philips MRI parts plays an important role in the imaging process. Their categorization-from RF coils to cooling systems-all plays a major role in the methodology pursued in the maintaining of such systems, in conducting whatever faultfinding may be necessary, and in the safe operation of such systems. Among such important components are RF coils, gradient coils, superconducting magnets, and cooling systems, all of which come into crucial play as one tries to achieve good diagnostic results while guaranteeing patient safety and system reliability. All these require regular servicing and timely replacement to avoid any kind of shutdown and prolong the useful life of an MRI system.

Attention to all these very important components-including comprehension of their functions and the required maintenance-allows healthcare facilities to optimize their MRI operations, offering better patient care through reliable and high-quality imaging.

You can find high quality Philips MRI parts in Technomed Medical Parts and Equipment.